Enhanced Force-Feed System for Peak Reliability

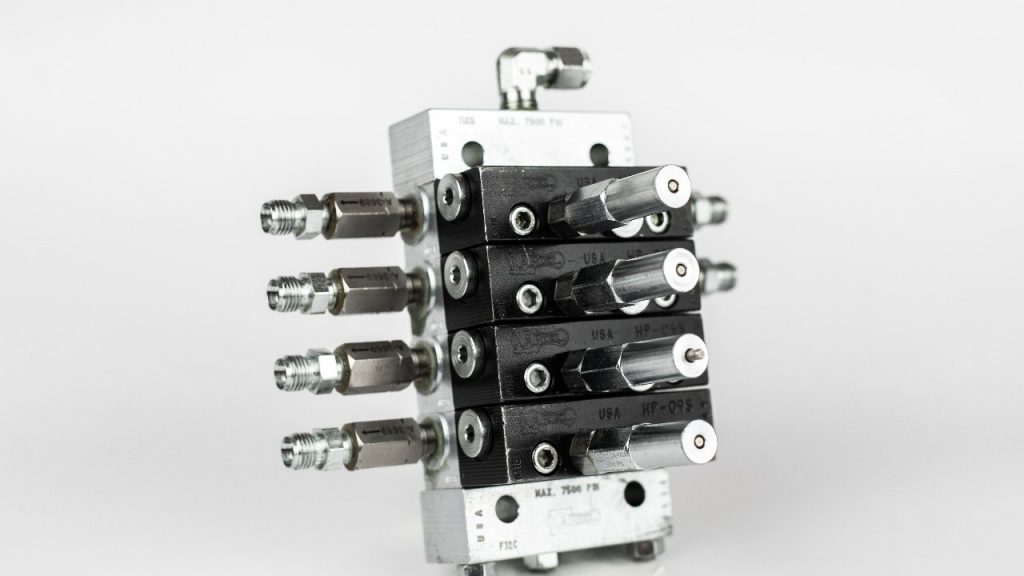

The force-feed lubrication system is designed to monitor and accurately deliver lubrication to vital parts of every Ariel compressor. Ariel has advanced the forced feed lubrication system to offer the following benefits:

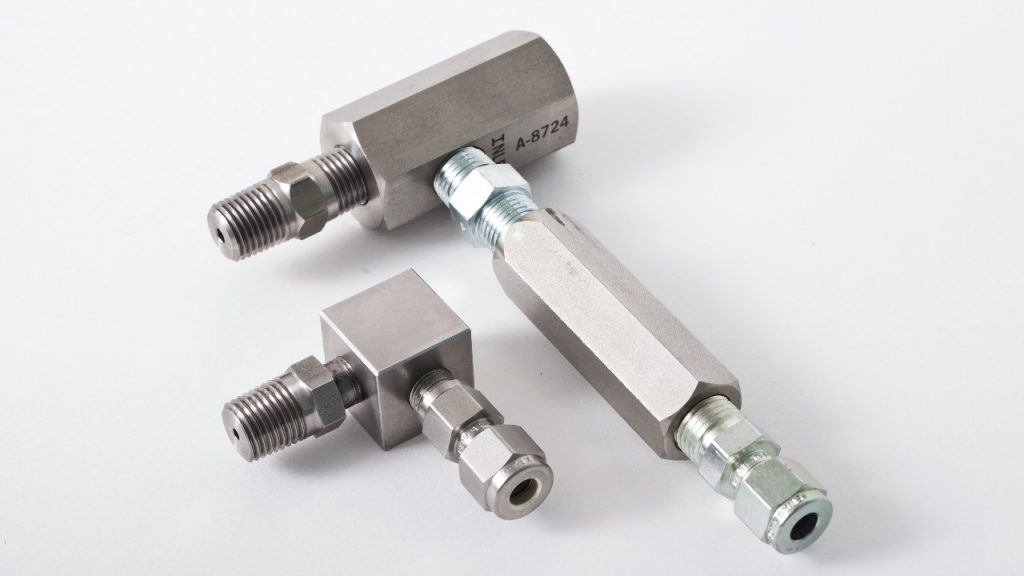

One check valve with fewer fittings and potential leak points is now used for all pressure ranges. Reduction in size and weight minimizes the effects of vibration for increased reliability.

The ARV is an auto-resetting device that will replace rupture discs to provide force-feed system overpressure protection. In the event of an overpressure event, the ARV opens and lubricant from the pump outlet is recirculated to the pump inlet manifold, containing the lubricant. In a sustained overpressure event, the no-flow device will time out, shutting down the unit.

Available as a new unit option or aftermarket addition to simplifying troubleshooting.

Redesigned with increased accuracy to avoid nuisance unit shutdowns.

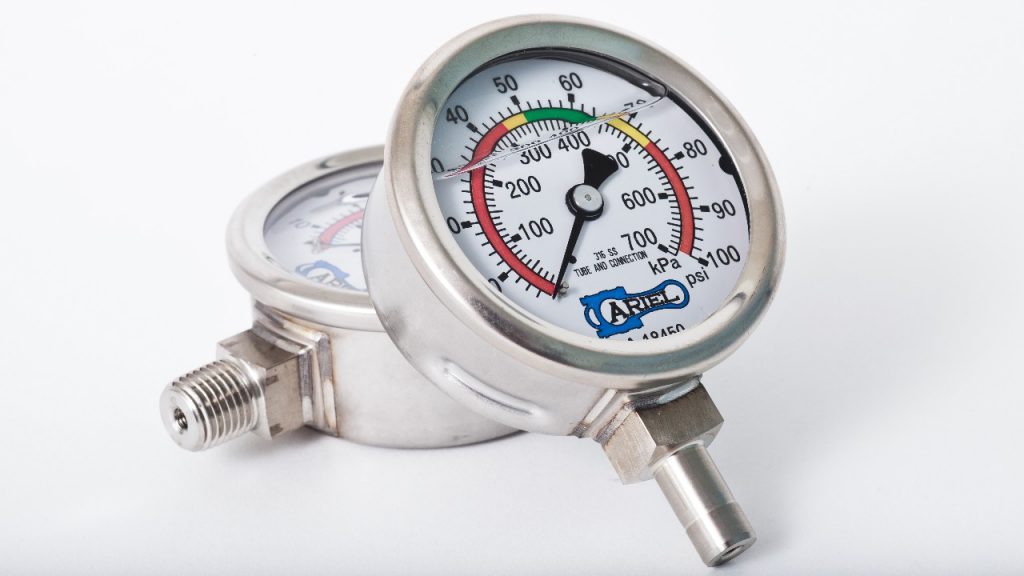

Pressure gauges installed on each balance valve ease adjustment and maintenance on KBU:Z:B:V units.

Tube connections replace threaded connections to reduce fitting leakage, ease gauge face alignment and eliminate damage from over-tightening. Gauges have been repositioned below divider blocks for increased protection where possible.

Improved design offers better performance and quicker priming. Reduction in size and weight minimizes the effects of vibration and keeps components out of the way.

Increased selection of ATEX certified no-flow monitoring devices to meet your needs.

Improved manufacturing techniques reduce leakage at threaded connections and prevent thread damage.

Redesigned pump assembly improves pump-priming, reduces rolling resistance on the camshaft, prevents water intrusion into the lubricator box, and minimizes connection leakage.